WIlo Rexa Cut UNI |

Materials

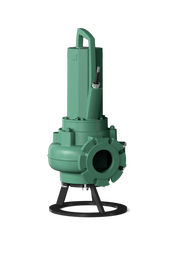

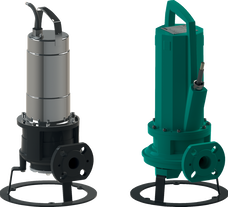

Description/constructionSubmersible sewage pump as submersible monobloc unit for stationary and portable wet well installation.

Hydraulics

The outlet on the pressure side is designed as horizontal flange connection. The maximum possible dry matter is 8 %. Vortex impellers are used as the impeller shape. A pump support foot is integrated into the hydraulics housing.

Motor

The motors available are surface-cooled motors in single-phase version (with built-in operating capacitor) and three-phase version for the direct starting. The waste heat is given off directly to the surrounding fluid via the motor housing. These motors can operated immersed in continuous duty (S1) and non-immersed in short-time duty (S2) or intermittent periodic duty (S3).

Furthermore the motors are equipped with thermal motor monitoring. This protects the motor windings against overheating. For units with single-phase AC motors this is built-in and switches automatically. I.e. if the motor is switched off due to overheating and then cools down it is automatically switched on again. Bimetallic strips are used for this as standard.

The connection cable has a length of 10 m as standard and is available in following versions:

Seal

There is a sealing chamber between the motor and hydraulics. This is filled with medicinal white oil. The seal on the fluid side is provided by a mechanical seal.

- Motor housing: 1.4301

- Hydraulics housing: PP-GF30 (copolymer)

- Impeller: PP-GF30 (copolymer)

- Static gaskets: NBR

- Sealing on pump side: SiC/SiC

- Sealing on motor side: NBR (V05), C/MgSiO4 (V06)

- Shaft end: Stainless steel 1.4401

Description/constructionSubmersible sewage pump as submersible monobloc unit for stationary and portable wet well installation.

Hydraulics

The outlet on the pressure side is designed as horizontal flange connection. The maximum possible dry matter is 8 %. Vortex impellers are used as the impeller shape. A pump support foot is integrated into the hydraulics housing.

Motor

The motors available are surface-cooled motors in single-phase version (with built-in operating capacitor) and three-phase version for the direct starting. The waste heat is given off directly to the surrounding fluid via the motor housing. These motors can operated immersed in continuous duty (S1) and non-immersed in short-time duty (S2) or intermittent periodic duty (S3).

Furthermore the motors are equipped with thermal motor monitoring. This protects the motor windings against overheating. For units with single-phase AC motors this is built-in and switches automatically. I.e. if the motor is switched off due to overheating and then cools down it is automatically switched on again. Bimetallic strips are used for this as standard.

The connection cable has a length of 10 m as standard and is available in following versions:

- With bare cable ends

- With plug

- With float switch and plug

Seal

There is a sealing chamber between the motor and hydraulics. This is filled with medicinal white oil. The seal on the fluid side is provided by a mechanical seal.

Related Products

|

Contact Us

Al Qusais Industrial Area 1, Dubai, UAE P.O.Box 12940 Mob: +971 56 329 5097 Tel: +971 4 252 2966 Email: [email protected] |