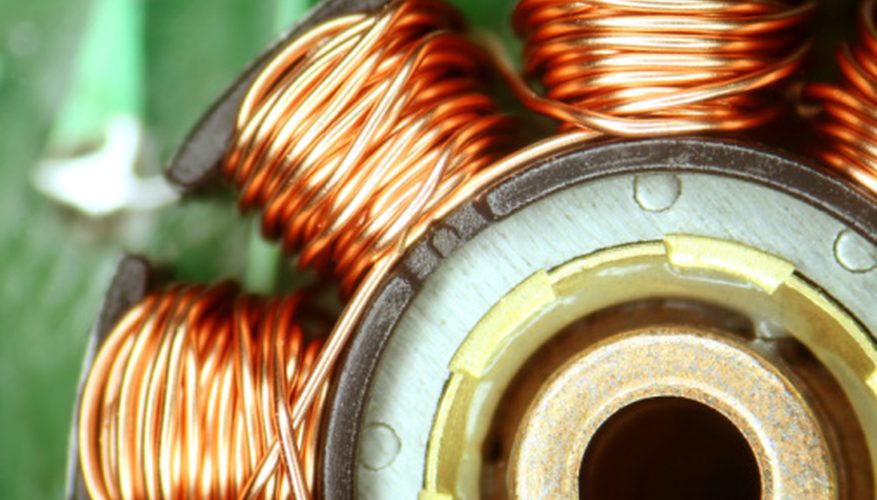

Electric Motor Rewinding |

|

One of the most common faults that occur with pumps is that the electric motors that they use burn out. If this happens, the easiest and most effective solution is to replace the motor. However, this is no the case with older motors with special shafts and cannot be replaced so easily. This means a rewind needs to be carried out to get it working again.

Rewinding an electric motor isn't a simple task; it is a very specialized skill. The correct terminology for rewinding a motor is Armature winding. Motor rewinders tend to use the existing windings of the motor to gather the data such as its connections, turns on each coil and copper sizes. There are various reasons why electric motors burn out and need to be rewound. These are the most common causes: Single Phased- This happens when one of the phases on the supply has been lost. The motor would continue to run as it would still have the coils from the other two phases. But over time it would get to a point where the controls would trip it out as it would pull excessive current. Dead short to earth- This happens when the insulation between the coils (winding) and the casing on the stator break down and allow an electrical current to travel between the two, which in turn would cause a hot spot on the copper and eventually would blow a hole through them. Short between Phases- This happens in a similar way to a dead short to earth, but this time is due to the insulation between the coils in each phase. This would also cause a hot spot and blow a hole in the copper. This generally happens when a phase is lost from the supply as well. Complete Burn out- This normally occurs when another part on the motor fails, such as the bearings stalling the rotor. The motor rotor would seize in the one positon, consequently causing the winding to pull extremely high amps which in turn fris the copper all at the same time. Air Flow- Each motor has a running temperature and is cooled via its own fan. These are either installed internally or externally. If the temperature of the motor increases above its recommended running temperature, this could result in the motor burning out as the coils would get hot and cause the insulation to break down. |

Need a Quote

Working on a project and need quoting? Contact us today for a free quote |

Related Products

|

Contact Us

Al Qusais Industrial Area 1, Dubai, UAE P.O.Box 12940 Mob: +971 56 329 5097 Tel: +971 4 252 2966 Email: [email protected] |